(2007 – 2009) Porsche 911 Turbo (997) – Ultimate Guide

The sixth generation of the 911 series’ top-of-the-range model will be celebrating its world premiere on February 28, 2006 at the Geneva Motor Show and will be available in German dealerships as from June 24, 2006.

The 911 Turbo (Type 997) now has an output of 353 kW (480 bhp) at 6,000 revolutions per minute, 60 bhp more than its predecessor (Type 996). The specific output of the 3.6-litre boxer engine thus climbs to a new all-time high of 98 kW (133 bhp) per liter of displacement. Rated torque has been increased from 560 to 620 Newtonmeters. The speed range in which this power is available has also been extended. While the previous model’s maximum torque was available between 2,700 and 4,600 revolutions per minute, the corresponding figures are now 1,950 to 5,000 revs.

These improvements are translated into driving performance. The new 911 Turbo with six-speed manual transmission requires 3.9 seconds for the standard sprint from zero to 100 km/h. The coupé reaches the 200 km/h mark in 12.8 seconds. And just 3.8 seconds are all it takes for the most powerful series-built 911 model of all time to accelerate from 80 to 120 km/h in fifth gear. Despite these enhanced performance statistics, Porsche developers succeeded in reducing average fuel consumption by one tenth to 12.8 liters per 100 kilometers.

The 911 Turbo with the optionally available Tiptronic S automatic transmission puts in an even more impressive performance. An optimized setup gives the vehicle the wherewithal to power from zero to one hundred in just 3.7 seconds and to reach 200 km/h after a mere 12.2 seconds.

The Turbo with automatic transmission also has the advantage when it comes to flexibility. In penultimate gear it accelerates from 80 auf 120 km/h in 3.5 seconds. Fuel consumption by the Tiptronic S variant is 0.3 liters lower than that of its predecessor: 13.6 liters in accordance with the EU standard. Both transmission variants have a top speed of 310 km/h.

The vehicle’s flexibility can be enhanced even further with the optional ‘Sport Chrono Package Turbo’, available for the first time. Here the driver selects the sports button’ adjacent to the gear lever to activate a short-time “overboost” at full throttle. This increases boost pressure in the mid speed range by 0.2 bar for up to ten seconds; torque rises by 60 to 680 Newtonmeters. The time required by the 911 Turbo with manual transmission for intermediate acceleration from 80 to 120 km/h is reduced by 0.3 seconds to 3.5 seconds.

These performance figures owe themselves to exhaust turbochargers with variable turbine geometry, featuring for the first time in a gasoline engine model. At the heart of this technology are adjustable guide blades, which direct the engine exhaust flow variably and precisely onto the turbine wheel of the exhaust turbocharger. The principle of variable turbine geometry unites the advantages of small and large exhaust turbochargers and leads to a discernable improvement in flexibility and acceleration, particularly at low speeds.

To transfer the available power to the road, the new generation of the 911 Turbo features a redesigned all-wheel drive with an electronically controlled multi-disc clutch. Porsche Traction Management (PTM) ensures variable power distribution to the two driven axles. Depending on the driving conditions, the all-wheel electronics system constantly determine the optimal torque distribution to ensure the best-possible drive. In practice this translates as high agility on narrow country roads, outstanding traction in rain and snow and optimal active safety even at high speeds. These properties make the Porsche Traction Management system in the new 911 Turbo one of the most powerful and, at the same time, lightest all-wheel systems on the market.

The new 911 Turbo’s driving performance is duly tempered by its brake system, which comprises monobloc fixed-caliper disc brakes with six pistons at the front axle and four at the rear.

In comparison with the Type 996, the diameter of the internally ventilated and perforated brake discs at the front and rear wheels has been increased by 20 millimeters to 350 millimeters. As an option, Porsche is also offering its optimized ceramic brake system, PCCB (Porsche Ceramic Composite Brake). The advantages of this high-tech material mean a reduction of 17 kilograms compared to the standard brake system, excellent fading stability owing to consistent friction values and absolute corrosion resistance. The brakes now have a diameter of 380 millimeters at the front axle and 350 millimeters at the rear.

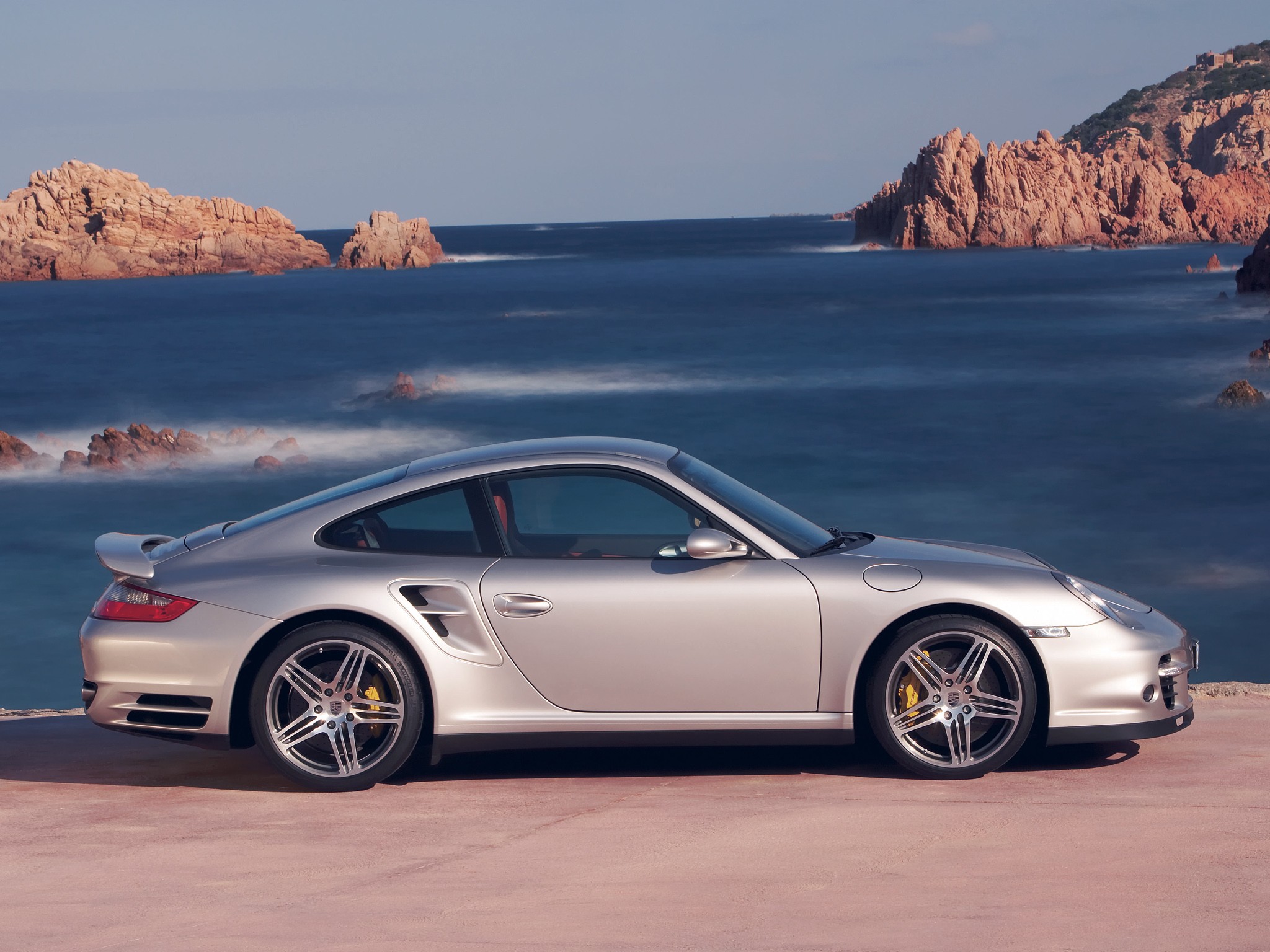

A characteristic design feature of the new 911 Turbo is the modified front end with its distinctive, tautly drawn cooling air inlets. In conjunction with the standard-equipment oval bi-xenon headlights, they define its unmistakable image. The harmonious front view is enhanced by widely placed and deep-set fog lights and by new LED flashers, which are situated in the lateral air inlets of the front end. From the rear perspective too, the Turbo takes on a more powerful appearance. This is due first and foremost to its tail end, 22 millimeters wider than that of the previous model, to which the redesigned wing spoiler element has been aligned. It now slopes downward slightly at the sides to nestle into the contours of the rear fenders. The lateral air inlets behind the doors have also been redrawn and, together with the new air ducts, afford a more efficient supply of cooling air to the charge-air intercoolers.

The basic Euro price for the 911 Turbo is 115,000 Euros. In Germany it is available for 133,603 Euros including value added tax and country-specific requirements. In the USA the 911 Turbo is priced at 122,900 Dollars (not including taxes), and will be available as from July 8, 2006.

In addition to the 911 Turbo, as a special surprise at the Geneva Motor Show, Porsche will be presenting another world premiere: the new 911 GT3. You will receive technical data and photos of this “racing car for the road” on February 28, 2006, the first press day in Geneva.

Pictures

Press Release

The sixth generation of the range-topping Porsche 911 Turbo provides towering performance in a practical, stylish and functional package suitable for everyday use. Power comes from a revolutionary, 480-horsepower, twinturbocharged, 3.6-liter boxer engine featuring Porsche’s first application of variable turbine geometry (VTG). The Porsche 911 Turbo also offers a redesigned, electronically controlled all-wheel-drive system, and evolutionary styling.

Variable Turbine Geometry (VTG)

For the first time, the power unit of the Porsche 911 Turbo features an exhaust gas turbocharger with variable turbine geometry (VTG). VTG provides for efficient control of the exhaust gas flow throughout the entire range of engine speed, guiding the flow of air in exactly the right direction and at the right angle to the turbine blades. The result is yet another increase in engine output, despite engine capacity remaining unchanged at 3.6 liters, up from 420 horsepower to 480 horsepower. Maximum torque, in turn, is up from 415 lb.-ft. to 460 lb.-ft., and meaningful twist is on tap beginning at a low 1950 rpm.

New all-wheel-drive system management

Benefiting from a newly developed all-wheel-drive management system, the Porsche 911 Turbo is able to convert the enormous power of the engine into practical performance on the road with optimum traction in all conditions. The standard Porsche Traction Management (PTM) system features an electromagnetically controlled multiple-plate clutch for distribution of power front-to-rear. Responding within 100-milliseconds to both driver input and road conditions, PTM is able to immediately transmit more power to the wheels that can use it best whenever required.

Quick with the six-speed manual transmission, even quicker with the 5-speed Tiptronic® S

Equipped with a six-speed manual gearbox, the Porsche 911 Turbo accelerates to 60 mph in only 3.7 seconds (0-100 km/h, 3.9 sec.). Equipped with the optional Tiptronic S, the car completes the same sprint in only 3.4 seconds (0- 100 km/h, 3.7 sec.). This makes the Porsche 911 Turbo the first sports car from Porsche with quicker acceleration with the automatic transmission than with the manual. This is the result of the interaction of the turbochargers with their variable turbine geometry, the Porsche Traction Management, and the new Tiptronic S set-up.

Extra boost: Sports Chrono Package Turbo with Overboost

For the first time the optional Sports Chrono Package Turbo provides a brief Overboost of power. With the Sport button engaged, and under full throttle during mid-range engine speeds, turbocharger boost pressure is temporarily increased, boosting torque by 45 lb-ft (60 Nm) to a staggering 505 lb-ft (680 Nm). This Overboost is an advantage in short, interim acceleration and overtaking maneuvers.

Active suspension is standard equipment

The 2007 911 Turbo arrives standard with Porsche Active Suspension Management (PASM), giving the driver the choice of either a sporting but comfortable standard set-up (Normal mode) or a particularly sporting and firmer set-up (Sports mode).

Upgraded braking system

The 2007 Porsche 911 Turbo features a brake system even more efficient than on the former model. The brake concept on the front wheels has been carried over from the Carrera GT, with six-piston brake calipers in conjunction with 350mm (13.78″) brake discs ensuring impressive stopping power. The new brake configuration also feeds more brake power to the rear wheels, where four-piston brake calipers again interact with brake discs measuring 350mm in diameter. Two other features are pre-loading of the brake system and Brake Assistant, both serving to shorten stopping distances even further when applying the brakes suddenly. The Porsche 911 Turbo is also available as an option with Porsche Ceramic Composite Brakes (PCCB® ) for truly outstanding braking qualities ensured by ceramic brake discs, and further developed in even larger dimensions than before.

5-speed Tiptronic S automatic with new dynamic driving functions

Whenever the driver takes his foot off the gas pedal abruptly, the new Fast-Off function prevents the Tiptronic S transmission from upshifting, even if the driver does not release the gas pedal completely. This improves driving dynamics, particularly on winding or serpentine roads and. The new Fast-Back function enables the driver to downshift more quickly when applying the brakes in a sporting style, when moving over quickly from the accelerator to the brake pedal. When braking into a bend, for example, Fast-Back automatically helps select the proper gear for subsequently accelerating out of the bend.

High standard of passive safety

Like the entire 911 model series, the new top-of-the-range Porsche 911 Turbo offers a high standard of passive safety. Apart from full-size airbags for the driver and front passenger, the entire range of six airbags includes two head airbags in the side window sills interacting in a side-on collision with thorax airbags in the front seat backrests. Porsche was the first manufacturer to offer this additional safety benefit.

Reversing the weight spiral

Despite the change in dimensions and new functions, the Porsche 911 Turbo is lighter than its predecessor – a benefit aided by the doors made completely of aluminum. Weighing just 11 kg (24 lb.), the doors, together with other lightweight features, help to give the car a DIN unladen weight of 3495 pounds (1585 kg). Despite a wider range of equipment, this is 11 pounds (5 kg) lighter than its predecessor, and the power-to-weight ratio, in turn, is an outstanding 7.28 pounds per horsepower.

Innovative technology for stunning performance figures

Offering a truly cutting-edge package of new and innovative technology features, the 2007 Porsche 911 Turbo sets an unprecedented benchmark in driving dynamics. The key elements of this package are the two turbochargers which for the first time featuring variable turbine geometry (VTG), as well as Porsche’s newly developed and fully controlled all-wheel-drive: Porsche Traction Management (PTM).

Interacting efficiently with one another, these two systems offer the driver an even wider performance envelope. Accelerating all-out with the standard six-speed manual gearshift, the Porsche 911 Turbo reaches the 160 km/h-mark (99 mph) in just 8.4 seconds. Combining the new turbocharger technology and Porsche Traction Management with the newly optimized Tiptronic S transmission allows the 2007 Porsche 911 Turbo to reach this same mark in only 7.8 seconds. With either transmission, top test-track speed is 193 mph (310 km/h).

Evolutionary styling

The 2007 911 Turbo rests atop the 911 model range not only on account of its supreme performance, but with exterior design which is more expressive than that of the former model. Strikingly chiseled intake air scoops, with integrated LED directional indicators, and foglamps moved far to the outside give the front end a unique, characteristic look. The rear end, in turn, now exudes an even more distinctive impression of power thanks to the wheel arches widened by 22mm (0.87″), and tailpipes raised and integrated into the rear clip. The side air intakes behind the doors have also been redesigned, contributing to the special look of the Porsche 911 Turbo.

Technology in progress: the first Porsche with variable turbine geometry (VTG)

The performance of the ’07 Turbo is attributable in particular to the newly developed turbocharger technology featured on the six-cylinder power unit. Using special materials extremely resistant to high temperatures, Porsche’s engineers have succeeded in developing an exhaust gas turbocharger with variable turbine geometry (VTG) which can withstand exhaust gas temperatures up to 1000°C (1830°F). This allows the technology to be successfully applied to a gasoline engine. A turbocharger with variable turbine geometry offers the advantages of both a small and a large turbocharger in one unit.

The result of this new technology is a significant increase in both power and torque. Maximum output of the flat-six power unit is now 480 horsepower (353 kW) at 6000 rpm, 60 horsepower (44 kW) more than on the former model – despite engine capacity remaining unchanged at exactly 3.6 liters. Peak torque, in turn, is up from 415 to 460 lb-ft (560 to 620 Nm) throughout a far wider engine-speed range. On the previous Porsche 911 Turbo peak torque was available from 2700 to 4600 rpm. The 2007 911 Turbo maintains its peak torque from 1950 to 5000 rpm, and shows far better response than engines with conventional turbochargers.

Overboost for even quicker acceleration

A new option the 2007 Porsche 911 Turbo is the Sports Chrono Package Turbo, which includes an Overboost function for even quicker acceleration. By depressing the dash-mounted button to activate the Sport mode, the driver is able to temporarily boost turbocharger pressure in the medium speed range for up to 10 seconds by approximately 2.9 psi (0.2 bar), increasing torque by another 45 ft-lb (60 Nm) to 505 ft-lb (680 Nm). With this mode engaged, the manual-transmission Turbo accelerates from 50 to 75 mph (80-120 km/h) in its second-highest gear in just 3.5 instead of 3.8 seconds, and in an even more impressive 3.3 instead of 3.5 seconds with the Tiptronic S.

New all-wheel-drive management in a Porsche sports car

The 2007 Porsche 911 Turbo combines more power and torque with a significant improvement in power transmission provided by new management of the car’s all-wheel-drive system. Standard equipment on the ’07 Turbo, Porsche Traction Management (PTM) combines the typical driving pleasure of a rear-engined, rear-wheel-drive Porsche with even greater stability, traction and handling agility. To achieve these capabilities, PTM transmits the ideal percentage of engine power to the front wheels via an electromagnetically controlled multiple-plate clutch. Operating within 100 milliseconds at the very most, PTM responds even more quickly than the engine to a change in load, and far more quickly than even the driver himself will notice. It is fair to say that Porsche’s new all-wheeldrive setup is almost looking ahead. On the road, this means superior agility on narrow country lanes, excellent traction, and a high standard of all-round safety even in extreme driving maneuvers at high speeds, or on wet or snow-bound surfaces. The new setup is also among the lightest all-wheel-drive systems on the market.

Active damper system for driver-selectable chassis characteristics

Equipped with Porsche Active Suspension Management (PASM), the Porsche 911 Turbo comes as standard with yet another active control system for a higher level of handling performance. This computer-based damper system benefits from direct interaction of PTM and Porsche Stability Management (PSM), with control functions matched even more closely to the car’s driving dynamics. The driver has the choice of the Normal and Sports mode, with continuous damper adjustment being more comfort-oriented or extra sporting and firm, depending on the chosen setting. In a nutshell, the Porsche 911 Turbo can adjust its chassis characteristics to the driver’s individual wishes and preferences.

Superior brake performance

Following Porsche’s straightforward safety philosophy, an increase in engine power always requires an appropriate increase in brake power. This is precisely why the front wheels now come with six-piston, fixedcalipers brakes with the swept area increased by 42 percent. Diameter of the inner-vented brake discs has also increased from 330 to 350mm (13.0 to 13.78-in.). In this process of upgrading the brake system, Porsche’s engineers have also given the rear brakes more power, again increasing the size of the brake components. This extra feed of brake power to the rear is made possible by enhanced axle load distribution and greater downforce acting on the rear axle. The brake discs at the rear now also measure 350mm in diameter and interact with fourpiston fixed calipers.

To reduce the transmission of brake heat to the hydraulic fluid, the pistons on the brake calipers are thermally separated from one another by insulating ceramic inserts, protecting the brake fluid from overheating even under extreme conditions.

Since even more kinetic energy is now converted into heat when applying the brakes, optimized ventilation of the brakes ensures more efficient cooling. The air flow required for this purpose is guided through two openings in the front spoiler—with larger cross-sections than the previous model—to an air duct integrated in the front underfloor cover. Cooling air then flows from there to the front axle. The brake air spoiler fitted to the front axle is also larger than before, sending approximately 6 percent more cooling air to the front brake calipers and discs.

The 2007 911 Turbo is Porsche’s first production car to feature active ventilation of the rear brakes. Cooling air is fed via NACA ducts beneath the floor of the car through a flow channel. Brake air spoilers fitted on the rear suspension enhances the overall efficiency of the cooling system by another 14 percent.

Dual brake servo for a further reduction of pedal forces

Like the 911 Carrera 4 models, the Porsche 911 Turbo features a 9-inch dual brake servo instead of the conventional 10-inch single servo to boost brake pressure. Compared with the conventional single servo unit on the former model, the dual brake servo covers an effective brake area approximately 45 percent larger than before. In conjunction with optimized brake force distribution, this reduces pedal forces by approximately 20 percent. The larger master brake cylinder, in turn, guarantees a sporting and precise feeling on the brake pedal, with easily optimized “dosage” of the brakes typical of Porsches.

Impressive drag coefficient

Boasting its new tailor-made suit, the 2007 Porsche 911 Turbo offers excellent aerodynamics. Despite the wider body, the greater intake of cooling air, and 19-inch wheels, the drag coefficient remains unchanged at a Cd of just 0.31. At the same time Porsche engineers reduced lift on the front axle, and once again increased downforce at the rear, partially the result of extending the newly contoured split wing. Even at top speed, the driver enjoys superior stability, and clear-cut, easily calculable reactions.

A number of detailed improvements serve to optimize the flow of air on and around the front axle. The newly designed spoiler lip on the front air dam, for example, reduces the flow of air beneath the car and thus serves to minimize lift forces acting on the front axle. The new design of the side sill covers, in turn, not only harmonizes the looks of the car, but also ensures a precise and ultra-smooth flow of air to and around the wide wheel arches at the rear. Further back, spoilers in front of the rear wheels make the flow of air around the wheels smooth and aerodynamic.

The rear wing: more downforce, less flow loss

Introducing the extendible split wing on the rear lid, Porsche’s engineers succeeded for the first time on the previous model to generate downforce on the rear axle without increasing air drag or resistance. The 2007 911 Turbo continues this principle with enhanced aerodynamic efficiency. With the wing being more efficient than before, the entire wing unit when extended has been lowered by 35mm (13.78″) in the interest of better aerodynamic balance. This serves to maintain the car’s excellent drag coefficient even though the pressure acting on the rear axle at top speed is up by 27 kg (60 lb.) And it is this enhanced traction and side support which the driver will feel and appreciate, particularly when changing lanes at very high speeds.

To match the wide body of the 2007 911 Turbo, the split wing is approximately 30mm (1.18″) wider on each side than on the previous model, and is contoured to match the body at either end. As in the past, it moves out at a speed of approximately 75 mph (120 km/h) and retracts again at approximately 50 mph (80 km/h).

Fully covered underfloor

As on the other models in the 911 model range, the underfloor of the Porsche 911 Turbo is covered almost completely to ensure consistent airflow conditions, reducing turbulence and air swirl to a minimum. On the manual gearbox model, the underfloor cover is made up of six polypropylene panels almost doubling the overall size of the underfloor cover versus the previous model. Four air ducts in the front underfloor cover serve to vent the final drive on the front axle. To maintain a good temperature balance in the manual gearbox and, in particular, in the high-performance Tiptronic S transmission, a special air vent in the rear underfloor cover again ensures a smooth but ample flow of cooling air.

Enhanced cooling concept with three heat exchangers

As before, two radiators ahead of the front wheels and a central radiator are fed with air through large openings in the front air dam, ensuring that approximately 4,000 liters (140 cubic feet) of air is able to flow through the heat exchangers every second at a speed of 300 km/h or 186 mph.

To meet the greater cooling requirements of the more powerful engine and to ensure an ample flow of cooling air, the entire air flow system has been modified by adding a special bypass. This connection between the cooling air intakes in the middle of the front air dam, and those on either side of the car ensure more efficient distribution of air to the three radiators at the front.

To further minimize air flow resistance, Porsche’s aerodynamicists have developed a special air flow diversion blade for the discharge air coming out of the central radiator. This guide blade directs the flow of air downstream of the radiator beneath the underfloor of the car, without increasing lift force. At the same time the guide blades for the side radiators have been enlarged to improve the flow of air. Through their optimized shape, the air flows in the proper direction without building up additional lift force in front of the wheels.

New aluminum doors reduce weight

In addition to the light-alloy front lid, another special feature on the 2007 Porsche 911 Turbo are the aluminum doors. Thanks to a special production technique, the doors weigh just 11 kg (24 lb.), reducing the weight of the car by 14 kg (31 lb.). The doors rest on a light-alloy pressure-cast frame, which is visible at certain points without any surface cover for the first time in a production car. This special frame offers not only the strength and stability required thanks to integrated reinforcements, but also reduces the individual components on the doors to just five elements. And like the steel doors on the Turbo’s “sister” models in the 911 range, the new aluminum doors outperform the usual safety requirements in a collision from the side. In a collision from the front, in turn, reinforcement of the door shaft by extrusion-pressed profiles beneath the doorsill serves to transfer the forces acting on the body to the rear end of the car, with additional protection of the passenger cell.

Light-alloy wheels in two-tone, tri-spoke design

Nineteen-inch forged wheels, developed exclusively for the 2007 911 Turbo in a two-tone, tri-spoke design, add a particularly stylish touch to the car. Apart from lower weight, forging technology helps reduce the cross-section of the spokes to a minimum, providing a clear, unobstructed view of the brake calipers.

Through their surface finish, the wheels on the Porsche 911 Turbo stand out from all other wheels on the market, and the high-gloss-polished outer surface forms an impressive contrast to the titanium-colored paintwork on the spokes.

The benefits of turbines with variable geometry

With its narrow flow cross-section, a small turbocharger will respond to even small amounts of exhaust gas by building up high flow velocity. Benefiting from this response, the compressor wheel pumps compressed air into the combustion chambers from low engine speeds, thus increasing the engine’s power density. The disadvantage is that flow resistance increases parallel to engine speed on account of the higher air throughput, generating high back-pressure and forcing some of the exhaust gas out of the engine through a wastegate or bypass valve. A large turbocharger, in turn, comes with exactly the opposite features: At low engine speeds its response is slow and sluggish due to the larger cross-sections and higher turbine masses, while exhaust gas back-pressure decreases as a function of increasing air flow.

Variable turbine geometry uses guide blades to simulate the cross-section of a turbocharger always optimized in size. At low engine speeds, the blades angle to form small air-flow openings. The exhaust gas flowing through a smaller cross-section is accelerated accordingly, hitting the turbine wheel with a high level of energy and therefore acting as a small turbocharger. This blade angle is maintained until the system has built up the required pressure—on the 2007 Porsche 911 Turbo this is approximately 14.5 psi/1.0 bar (at sea level, under full load, and at an ambient air temperature of 20° C/68° F).

With the flow of exhaust gas continuing to increase as a function of higher engine speed, the blades open up and regulate turbocharger pressure accordingly. The electronic management and the electrically driven control mechanism—the control of which are integrated into the engine’s Motronic management system—are set up to give the blades an adjustment period from “open” to “closed” of approximately 100 milliseconds. With the variable turbine geometry of the turbocharger being able to handle even the maximum flow of exhaust gas conceivable, there is no need for a bypass valve.

The air compressed by the turbochargers flows to two intercoolers (essentially the same intercoolers on the former model), although the supply and flow of air has been improved. At their narrowest points, the ducts behind the air intakes on the ’07 Turbo’s rear flanks are approximately 10 percent larger in their cross-section. This reduces flow resistance, and the more efficient intercooler helps increase both power and torque.

To reduce excess boost pressure on the throttle butterfly when quickly lifting off the throttle or in overrun, the 2007 911 Turbo features an automatic bypass valve which saves space via a new placement on the compressor housing.

High-tech materials for reliable turbo use in series production

Variable turbine geometry (VTG) has been used on diesel engines for over 10 years. The drawback, however, was that the systems used on diesel engines were not suitable for gasoline engines, mostly for thermal reasons. While exhaust gas temperatures at the point leading into the turbine on a diesel engine are between 700 and 800° C (1290 – 1470° F), the exhaust gas on Porsche’s turbocharged power units has a temperature of 1000° C (1830° F). This creates a significantly higher load and extra strain on the adjustable guide blades, demanding the utmost of the materials and construction method applied.

Only the use of materials extremely resistant to high temperatures and new simulation methods allowed the production of turbochargers suitable for regular use in a series production gasoline engine, with the long-term performance and life expectancy required. A further important factor is that Porsche’s engineers have developed a water cooling system including a follow-up pump to reduce the high temperatures of the components, over and above the existing cooling system.

VarioCam® Plus with greater valve lift

The combustion cycle on the 2007 Porsche 911 Turbo is masterminded by Porsche’s VarioCam Plus variable valve management in its most advanced form. VarioCam Plus changes both the valve lift and duration of the intake valves. This is done, first, by a vane cell adjuster able to infinitely vary the relative position of the camshaft versus the crankshaft throughout a wide crank angle range of 40 degrees. The valve lift adjustment system is made up of two intersecting, switching cup tappets operated by two cams on the intake camshaft varying in size.

In comparison with the previous generation Porsche 911 Turbo engine, the adjustment stroke range of the intake valves has been increased from 3.0 to 3.6 mm (0.12 – 0.14″). This allows the engine to cover a wider engine-speed and load range, with the small valve lift openings helping to enhance fuel economy, power, and emissions.

Sodium-filled exhaust valves with modified springs

The introduction of a turbocharger with variable turbine geometry also means an increase in exhaust gas backpressure on the Porsche 911 Turbo engine. To take this into account, the valve springs feature a modified construction ensuring that the valves continue to close properly and securely. With the valves closed, the springs create a higher closing force without changing the force exerted by the springs under maximum valve lift. This helps prevent increases in friction losses. As on the previous Turbo model, the exhaust valves are cooled by sodium. The valve shaft is filled with sodium, which liquefies at combustion temperatures, and dissipates heat from the valve face to the cooled valve shaft.

New intake system reduces flow losses and weight

Developing the Turbo engine, Porsche’s engineers have also developed an all-new intake system. Beyond the aesthetic improvements, they have optimized flow conditions in the intake manifolds from the air filter to the compressor in the turbocharger, and in the pressure pipes from the compressor to the throttle butterfly, reducing resistance forces in the process. The two halves of the intake manifold on the Porsche 911 Turbo are now formed of a single piece of synthetic material.

This new manifold serves to reduce weight by approximately 3 kilos and at the same time provides better flow conditions into the cylinder head. A new air filter housing is highlighted as the central unit in the new design of the engine compartment. A further advantage is that air filter change intervals have been extended from 40,000 to 60,000 kilometers (25,000 – 37,000 miles).

Engine block with unchanged dimensions

The engine block of the Porsche 911 Turbo has been carried over in its main features and components from the previous model without any changes. Hence, the 2007 Turbo also comes with a vertically split crankcase made of pressure-cast light alloy, and a crankshaft running in 8 bearings. Displacement is 3600cc, and as before, cylinder bore is 100mm (3.94″), and piston stroke is 76.4mm (3.01″).

Taking the higher turbocharger pressure and the greater strain acting on the engine’s components into account, Porsche’s engineers have reduced the compression ratio from 9.4:1 to 9.0:1.

The forged light-alloy pistons run in aluminum cylinder liners coated with Nikasil, an alloy made up of nickel and silicon. The engine block itself is built in a proven sandwich structure, with the camshaft housing, cylinder head and cylinder housing bolted to the crankcase.

Dry sump lubrication system unaffected by extreme dynamics

To ensure a safe and reliable supply of oil to the engine, a sports car capable of the longitudinal and lateral acceleration of the Porsche 911 Turbo inevitably requires dry sump lubrication. Accordingly, a total of nine oil pumps on the new power unit provide safe and reliable circulation of oil even under lasting horizontal forces. Two oil extraction pumps for the exhaust gas turbochargers, two oil extraction pumps on each of the cylinder heads, as well as two extraction pumps and one pressure pump in the crankcase ensure the standard of efficiency required. The extraction pump fitted at the front end of the crankcase in the direction of travel is new on the 2007 Porsche 911 Turbo engine, ensuring an additional supply of lubricant during extreme, prolonged deceleration. Total oil circulation in the system is approximately 11 liters (11.6 quarts) of 0W40 oil.

Fifteen percent better cooling ensured by second oil cooler

To meet the greater engine oil cooling requirements in the Porsche 911 Turbo, heat dissipated by the engine oil is transferred into the coolant by two oil/water heat exchangers instead of one, as on previous models. This increases oil cooling capacity by more than 15 percent.

The second oil/water heat exchanger is housed in the oil-reflow pipe feeding oil back into the oil tank. This ensures consistent oil pressure in the supply line, regardless of flow resistance. A further advantage is the better transition of heat to the coolant and, accordingly, the enhanced cooling effect.

Liquid-cooling for the first time on the turbocharger

For the first time, on the 2007 Porsche 911 Turbo, the turbocharger bearing case is now liquid-cooled. An additional pump increases the flow of coolant as required at low engine speeds, and ensures efficient cooling of the turbocharger even after the ignition is turned off after driving under high power.

Lighter, even more efficient exhaust system

The introduction of variable turbine geometry on the turbochargers required significant modifications and new developments in the exhaust system. One catalyst for each row of cylinders is placed close to the engine, and optimized secondary air injection (when starting the engine cold) improves exhaust emissions and enables the engine to fully comply with both EU4 and LEV II (USA) emission standards. Another advantage is the thin walls of the rear silencers reduce the overall weight of the exhaust system compared to the previous model by approximately 4 kg (8.8 lb.).

Adapted 6-speed manual

Despite its prodigious torque, the six-speed manual transmission on 2007 Porsche 911 Turbo enables smooth, precise and quick shifts. These traits are attributable to the hydraulically-boosted clutch, which keeps pedal forces sensibly low, and to the new set-up of the six-speed gearbox, which is based on the transmission featured in the previous generation Turbo.

In consideration of the higher engine output, the entire gearbox has been reinforced and the cooling system improved. Reinforcements have been made around the drive head (crown and plate wheel) and on the individual gear sets. Modification of the fins on the gear casing, and an additional vent opening in the underfloor cover serve to enhance the cooling effect. Structural reinforcements on the gear housing reduce the transmission of airborne sound waves.

As with the other models in the current 911 model range, gear ratios on the Porsche 911 Turbo have been modified from second to sixth gear to reflect the changeover from 18-inch to 19-inch wheels. Gearshift travel is about 15 percent shorter, again as on the other 911 models in the current range, due to the pivot point on the shift lever being moved to a different position. Triple cone synchromesh in first and second gear and dual synchromesh with carbon coatings on gears 3-6, in turn, serve to reduce gearshift forces. The use of carbon coatings enables the gears to handle higher loads, and improves gearshift feel while maintaining the same service life.

Tiptronic S optimized for VTG equipped Porsche 911 Turbo

One reason for the 2007 Porsche 911 Turbo’s quicker acceleration with Tiptronic S automatic transmission is the optimized interaction with the turbocharged engine and the new Porsche Traction Management (PTM) all-wheel-drive system. Also aiding the improved performance is the mechanical improvement of the planetary gears (which have also been strengthened) and the optimized gearshift process. Both gearshift and reaction times of the Tiptronic S transmission featured in the 2007 911 Turbo are quicker than before, and now also provide new Fast-Off and Fast-Back functions. Operation of the torque converter lock-up clutch has been significantly improved. By reducing torque converter slip, and adjusting to engine speed more quickly, the 2007 Porsche 911 Turbo reacts more quickly to the accelerator pedal for improved responsiveness, and a more connected feeling via the throttle.

Tiptronic S Fast-Off and Fast-Back for more intuitive and sporting experience

The new Fast-Off function prevents the transmission from upshifting when the driver lifts on the gas pedal abruptly. The driver is no longer even required to lift off the gas pedal completely, and the new Fast-Off function immediately improves the car’s driving dynamics, particularly on winding routes.

The new Fast-Back function allows the driver to downshift more quickly when applying the brakes under aggressive driving conditions. Whenever the driver changes over from the accelerator to the brake pedal within 1.5 seconds, Tiptronic S immediately downshifts a gear, even if the driver only touches the brake pedal hard enough to activate the brake lights. In all, Fast-Back shortens the reaction time of the first downshift while braking by approximately 30 percent.

When downshifting while braking with normal force, the system changes gears only as a function of the car’s actual deceleration, maintaining a certain time-lag between activation of the brake pedal before Tiptronic S actually downshifts.

The Fast-Back function operates on top of this brake downshift function and, for example when braking into a bend, automatically selects the optimum gear for subsequent acceleration out of the corner.

Yet another innovation is the “desired power function” offered by the optional Sports Chrono Package Turbo. If so optioned with the Tiptronic S transmission, an additional signal is sent to the engine management system for brief interim throttle, resulting in even quicker gearshifts.

Sports Chrono Package Turbo features

Available for the first time with Porsche’s optional Sports Chrono Package Turbo, the 2007 Porsche 911 Turbo, like the Carrera models, provides the choice of an even more sporting set-up of various vehicle functions, including engine management, and profiles of the Porsche Stability Management (PSM) and Porsche Active Suspension Management (PASM) systems. The 2007 911 Turbo highlights three new functions in its Sports Chrono Package Turbo: a more agile all-wheel-drive profile of the Porsche Traction Management (PTM), the use of first gear when setting off with Tiptronic S, and Overboost.

Overboost briefly increases turbocharger pressure when accelerating under full load. This innovative function is activated when the Sports button on the center console is depressed and the driver is applying full throttle. An arrow symbol in the turbocharger pressure display in the instrument cluster informs the driver that the car is in Overboost. This additional boost of turbocharger pressure is achieved by adjusting the turbocharger blades to increase maximum turbocharger pressure by approximately 2.9 psi (0.2 bar), in the engine speed range of 2100 to 4000 rpm.

Five basic Porsche Traction Management (PTM) functions for all conditions

Standard distribution of torque and engine power: Under regular driving conditions, PTM distributes engine power with infinite variability between the front and rear axle as a function of current, ongoing requirements. To do this, the system determines the need for engine power and torque on the front axle in millisecond cycles. Particularly at very high speeds, the driver will feel and benefit from a significant improvement of driving stability.

Pre-loading: Monitoring typical parameters, PTM is able to detect dynamic changes in driving conditions at an early point in time, and avoid wheel spin right from the start. When the driver starts the engine and sets off, for example, the system will determine how fast the driver is accelerating and how much throttle is being applied. So even before the engine is able to translate this request for acceleration into actual torque conveyed to the wheels, PTM closes the multiple-plate clutch sufficiently to prevent the wheels from spinning to the greatest possible extent. This, in turn, means that all four wheels receive maximum drive power when setting off in the interest of optimum acceleration.

Slip control: Due to its prodigious torque, the 2007 Porsche 911 Turbo may reach the traction limit on the rear axle when accelerating on a wet surface. So here again, PTM intervenes to a higher degree, with the multiple-plate clutch feeding more torque and, as a result, more drive power to the front axle. The Porsche 911 Turbo is the first model to monitor the car’s straight-ahead acceleration in this sophisticated manner.

Oversteer control: Whenever the rear end of the car swerves to the outside in a bend on account of adverse conditions such as a wet surface, more power is fed to the front axle in order to stabilize the car. A further advantage of PTM is that it is able to consider the steering angle in doling out power between the front and rear axles. So should the driver counter-steer with the car oversteering, PTM will adjust the flow of power to the front axle accordingly, stabilizing the car even more quickly. The same effect is also provided by the next function.

Understeer control: Should, conversely, the car tend to understeer with its front wheels “pushing” out of a bend, PTM will reduce the feed of engine torque and power to the front axle. Indeed, thanks to its sophisticated sensors, PTM responds in both cases before the driver even notices any instability. The result is quick and active stabilization of the car in fast and dynamic bends, with Porsche Stability Management (intervention of the brakes on a specific wheel) not being required as often.

Multiple-plate clutch with magnetic control

The key component within the drivetrain in Porsche’s active all-wheel-drive system is the newly developed multipleplate clutch within the front differentia. The multiple-plate clutch is controlled neither by a hydraulic system nor by actuators, but rather by electromagnetic management. Magnets operate a master clutch with three discs. The discs are connected to one another by a mechanical reinforcement element, which serves to actuate the main clutch, which is comprised of eight sets of friction discs.

The clutch is designed for a peak torque of 295 lb-ft (400 Nm) — more than sufficient, considering that the front wheels lose their grip even on a dry road at approximately 221 lb-ft (300 Nm).

The multiple-plate clutch runs in an oil bath integrated in the housing of the front-axle differential, and features its own oil circuit, complete with a separate circulation pump. The special ATF (automatic transmission fluid) used for this function needs to be exchanged only once every 90,000 km (56,000 miles).

A special PTM computer serves to mastermind the clutch, communicating via a CAN-bus network with important systems within the car, to determine wheel speed, lateral and straight-ahead acceleration, as well as the steering angle. One reason for the system’s fast response is that several control maps which analyze current driving conditions run in parallel to one another and not in series.

Optimized Porsche Stability Management (PSM)

Like the 911 Carrera 4 models, the 2007 Porsche 911 Turbo features Porsche Stability Management (PSM) with enhanced brake functions. One of these functions is pre-loading of the brakes help shorten stopping distances when fully applying the brakes. Whenever the driver lifts off the gas pedal abruptly – which is characteristic of an emergency braking scenario – the system instantly pumps brake fluid from the hydraulic PSM control unit to the brake calipers, eliminating the air gap between the brake pads and the brake discs. The pads are therefore already resting directly on the discs by the time the driver presses down the brake pedal. This means spontaneous deceleration and brake force.

The second new function added to PSM also helps in critical situations by ensuring a faster build-up of pressure in the brake circuit. The two crucial factors in this case are the speed and the pressure with which the driver presses down the brake pedal. Should the driver press down the brake pedal rapidly but not with full force, the hydraulic pump will offset the lack of pressure, initiating the ABS brake control mode on all wheels, ensuring optimum brake power for the shortest possible stopping distance.

The system also enables the driver to perfectly “dose” the brakes in typical Porsche style, should the driver prefers a sporting style of motoring. Should the driver fail to increase the pressure he is exerting on the brake pedal beyond a certain limit or should he take back the brake pedal, the additional pressure built up by the system is reduced. Yet a further point is that the pressure booster does not always cut in under all conditions. If the driver is already pressing down the brake pedal so hard that all four wheels have optimum stopping power, any further increase in pressure would be unnecessary and the assistance function therefore remains inactive. The final criterion is that this new function is always deactivated when the driver has pressed the Sports button or when the car is in the “PSM off” mode.

Optional mechanical locking differential

If equipped with the six-speed manual transmission, the 2007 Porsche 911 Turbo is also available with an optional, mechanical locking rear differential with asymmetric power distribution. The locking factor, as on the previous model, is 22 percent under power and 27 percent on overrun. The locking differential complements the qualities of the Porsche Traction Management (PTM) all-wheel-drive control system. Whenever the driver prefers a particularly aggressive style of motoring in corners, for example, the mechanical differential lock allows higher traction on the inner wheel. In that case the automatic brake differential intervenes later than usual to allow a higher threshold of driving dynamics.

Suspension geometry upgraded for the Porsche 911 Turbo

The mechanical components featured on the suspension of the Porsche 911 Turbo are based on the “regular” components already used on the Carrera 4S, but have been further upgraded in various respects to reflect the car’s performance and higher loads. Focusing on the Turbo and its specific requirements, Porsche’s engineers have reconfigured and upgraded both the springs and dampers.

A further distinction versus the suspension on the Carrera 4 is the rear axle subframe. On account of its dry sump lubrication, the engine of the Porsche 911 Turbo is mounted somewhat differently and thus needs additional space around the subframe. The new subframe is therefore leaner in design and, for reasons of strength and stability, is made of steel instead of aluminum.

The complete chassis and suspension of the Porsche 911 Turbo is significantly lighter than the suspension on the previous model. The four lightweight spring struts alone reduce the overall weight of the suspension by 2.4 kg (5.3 lb.). A further point is the wider track of the new model which offers handling benefits. The front track is 18mm (0.71″) wider, while the rear track is 20mm (0.79″) wider.

The steering on the 2007 911 Turbo comes from the new generation of the 911 Carrera. Compared to its predecessor, the new top-of-the-range 911 offers a variable steering ratio. The variable ratio offers the driver not only enhanced agility particularly on winding roads, but also improved driving stability at very high speeds.

Tire pressure monitoring featured as standard

To enhance active driving safety, the Porsche 911 Turbo comes as standard with Porsche Tire Pressure Control (TPC) which continuously monitors air pressure in each tire. Through its warning function, TPC not only offers extra safety against possible tire damage, but in particular monitors any gradual loss of pressure from the tires, thus preventing inconsistent, unequal tire wear and excessive fuel consumption.

For extreme requirements: Porsche Ceramic Composite Brakes (PCCB)

The 2007 911 Turbo has available as an option Porsche’s well-known Porsche Ceramic Composite Brakes (PCCB). Benefiting from the high-tech ceramic material, the brakes respond even more quickly to the driver’s commands, remain extremely stable even under heavy use with virtually no fading thanks to their consistent frictional coefficient, and are absolutely immune to corrosion.

The Porsche 911 Turbo comes with enhanced brake disc technology using an even stronger material for minimum abrasion, and inner cooling ducts in an ‘Arcus’ design for enhanced cooling and brake stiffness. To increase braking power on the 2007 Porsche 911 Turbo, PCCB brake disc diameter on the front axle is up to 380mm (14.96″) from (350mm/13.78″) on the previous model, precisely the same diameter as those featured on the Porsche Carrera GT together with its six-piston fixed calipers.

At the rear, in turn, four-piston fixed calipers act on brake discs measuring 350mm in diameter. And despite the larger brake discs, PCCB is approximately 17 kg (37 lb.) lighter than the standard brake system with cast iron discs.

Porsche’s all-round safety system

The driver and passengers of the 2007 Porsche 911 Turbo are protected by all the passive safety features already admired as standard in the current 911 model range. This includes three-point inertial reel safety belts on all seats, complete with a belt-latch tensioner and belt-force limiters in front. The six airbags consists of two full-size two-stage frontal airbags and the trendsetting Porsche Side Impact Protection (POSIP) system.

Over and above door reinforcements, the POSIP system is made up of a thorax airbag on the outside of each seat backrest and a head airbag in each door. Porsche was the first car maker in the world to feature this technology.

In a collision from the side, the head airbag inflates from bottom to top to form a flat cushion with a total capacity of 8 liters, helping prevent the occupant’s head from impacting the side window.

Sophisticated leather interior standard

Based on the interior design of the current generation of the 911 Carrera, the interior of the Porsche 911 Turbo has been fully renewed and features leather upholstery and trim as standard. Like the other current 911 models, the more spacious interior features a lowered seating position, pedals moved forward, additional steering wheel range of adjustment (40mm, or almost 1.6″), and an electrical steering wheel lock. The instruments, with their aluminum-colored faces, come in Porsche’s characteristic 911 design boasting the “Turbo” script in the tachometer.

White, light-emitting diodes make the faces of the instruments brighter at night, and for the first time turbocharger boost pressure is also shown as a bar diagram in the round central instrument, the scale in the graph extending up to 1 bar or even 1.2 bar upon activation of the optional Sports Chrono Package Turbo. The car’s new interior design also features a gearshift lever in special “Porsche Turbo” look.

Like its predecessor, the Porsche 911 Turbo comes standard with Porsche Communication Management (PCM), including DVD-based navigation. The new standard BOSE Surround Sound System comprises 13 speakers and a seven-channel digital amplifier. As an option, PCM may be upgraded through the addition of a telephone module complete with an electronic logbook that can help easily track business use of the car. Significantly enhanced in the new generation of the Porsche 911, PCM now boasts an extra-large 5.8-inch display. An MP3-compatible CD player is fitted just above the display.

The DVD-drive for vehicle navigation housed in the luggage compartment offers much faster access to data than the former CD-based unit. With data being provided more quickly, the system is able to calculate navigation routes faster than before, just as the map update rate has been significantly enhanced. A further improvement is the greater number of zoom stages on the maps, now totaling 23 different levels, enabling the user to consult the maps in very fine stages up to a resolution of just 50 meters (165 ft.)

Additional standard features on the 2007 911 Turbo include rear-view mirrors with an automatic anti-dazzle function, and a theft warning system monitoring the car with radar sensors for the interior and contact sensors for all the door and lid latches.

The Porsche 911 Turbo can be further personalized by additional special features including the Park Assistant using ultrasound to measure the distance from obstacles in the vicinity of the car and, where necessary, warning the driver of a possible impact. Another special option is the programmable HomeLink System. A fully integrated garage/gate opener able to replace up to three transmitters, it can also be used for illumination or alarm systems. Further options include an powered steel sliding/lift sunroof and a roof-transport system.

Extended Service Intervals

In everyday use, the driver of the 2007 Porsche 911 Turbo benefits significantly from the vehicle’s very low cost of maintenance for an ultra-high-performance sportscar. Despite the far wider range of equipment and the more sophisticated technical components featured in the 2007 911 Turbo, Porsche has succeeded in extending the service intervals for this new model and reduced the amount of service required in each case. Like the current 911 Carrera models, the Turbo has service intervals of 30,000km (18,500 mi.), instead of the former 20,000km (12,500 mi.) interval. This equates to a 21-percent drop in service costs. Should the driver not cover the distance of 30,000km required for regular service, the car should be inspected at least once every two years.

Low cost of repair

A further advantage of the 2007 Porsche 911 Turbo is that a number of individual improvements and modifications make it less sensitive to minor damage and reduce the cost of repair accordingly. As a result, the Porsche 911 Turbo ranks far and wide as No. 1 in its class in terms of low insurance premiums.

Impact absorbers in the bumpers, to mention just one example, protect the body in minor collisions at both the front and rear from damage requiring elaborate repair. Fastened to the body by clips, the entire front section is very easy to exchange in a quick and convenient process. The particular configuration of the lines leading to and from the radiators at the front of the car, as well as the modification of connections with rapid-action fastenings throughout the entire cooling system, help to reduce the work required in the case of repair and, accordingly, the overall cost of repairing the car.

The 2007 Porsche 911 Turbo went on sale June 24, 2006 in North America. Pricing for the model in the U.S. and Canada were $122,900 (USD) and $170,700 (CAD) respectively.