2011 Porsche 918 RSR Hybrid Concept Car – Ultimate Guide

Made as a demonstrative show-car, the 918 RSR ‘Racing Lab’ is part of a new initiative called Porsche Intelligent Performance which will likely develop hybrid racing cars for outright victories at events like the 24 Hours of Le Mans. Premiere on January 10 2011 at NAIAS North American International Auto Show in Detroit, this is a very beautiful, but confusing car. The 918 RSR concept car is a mix between a racing car and a street car. It is not a full race car and it definitely isn’t a street car. It has a 3.4 liter V8 with 414kW @ 10,300 rpm plus 2 electric motors woth 75 kW each (peak power 564 kW). The new project will be developed under the direction of engineer Wolfgang Durheimer and Wolfgang Hatz who will oversee drive-train development as Porsche’s new chief engineer.

KERS

There are different Kinetic Energy Recovery Systems engineered. In the F1 cars the electric motor/generator is connected to the engine and therefore the rear wheels and the energy is stored in the supercapacitor (they are able to store energy 100 times faster than regular batteries). The system Porsche used in the 918 RSR, is somewhat different.

KERS/hybrid system in 918 RSR concept car

The 918 RSR concept car looks like the 918 Spyder, but the hybrid concept is from the 911 997 GT3 R Hybrid racing car and not from the 918 Spyder. The internal combustion engine and gearbox in the 918 RSR are developments based on the units from RS Spyder racing car.

There are two electric motors/generators installed on the front axle and the energy is stored in the flywheel capacitor, which is basically also an electric motor. The flywheel runs on ceramic bearings and operates in vacuum, so it doesn’t wind down so quickly. When driver presses the brake pedal, the electric link between the motors/generators and the flywheel capacitor is established. Now, the electric motors also help to brake the car, meaning they help to reduce the brake disc temperatures and wear. If you would have the electric motors connected to the capacitor all the time, it would decrease the power of the car, so it is connected only during braking and acceleration.

In order to spin the flywheel to its maximum of 36.000 rpms, it takes many pre-corner braking. At the push of a button, the pilot is able to call up the energy stored in the charged flywheel accumulator and use it during acceleration or overtaking manoeuvres. The flywheel is braked electromagnetically to supply up to 150 kW from its kinetic energy to the electric motors on the front axle. This additional power is available for around 8 seconds when the flywheel is spinning at its maximum speed.

The front electric motors also offer a torque vectoring function by means of variable torque distribution between left and right front wheels. This improves traction and steering response while exiting corners.

Launch Videos

At the 2011 North American International Auto Show in Detroit, Porsche debuted their latest concept, the Porsche 918 RSR. Taking proven technology from the race-track with the GT3 R Hybrid, the 918 RSR utilized a flywheel energy recovery system for added power and traction.

While at the Pebble Beach history weekend, the Porsche Designer Manager of Sports Cars, Anthony Hatter, details the design process and current status of Porsche’s upcoming hybrid supercar, the 918 Spyder. While the displayed Porsche 918 RSR is a conceptual study, Hatter discloses that many of its exterior design elements were taken from past Porsche race cars, while the new production 918 Spyder will do much of the same.

The 918 RSR was shown to the European public for the first time in Geneva. Get up close and personal with the hybrid race lab in this video.

Porsche 918 RSR Hybrid Concept Press Release

DETROIT – January 10, 2010 — With the world debut of the spectacular 918 RSR “racing lab,” Porsche AG today highlighted its continued and intensive focus on combining ultimate performance and high efficiency in the field of hybrid technology. The fourth hybrid vehicle presented by Porsche in the last twelve months, the extreme two-seat coupe reveals what happens when the technology fitted to the 911 GT3 R hybrid and the design of the 918 Spyder are fused to a modern, innovative super sports car.

Flywheel technology from the GT3 R Hybrid

With its highly-efficient flywheel accumulator, the 911 GT3 R Hybrid racing car was an attention magnet on Germany’s Nürburgring Nordschleife, America’s Road Atlanta and China’s Zhuhai racetracks. It demonstrated its performance potential under racing conditions against very tough competitors, showing competitiveness, high reliability and exemplary fuel efficiency combined with extraordinary performance.

Like that car, the 918 RSR – the motorsports-oriented version of the 918 Spyder – obtains its additional power from its own vehicle dynamics under braking.

The 918 RSR’s mid-mounted V8 engine is a development of the direct-injection engine from the successful RS Spyder race car, and now offers an output of 563 hp at 10,300 rpm. Two electric motors powering the front wheels each contribute 75 kW; leading to a peak power output of 767 hp from the hybrid system.

At the front axle, the two motors offer a torque-vectoring function to increase agility and improve steering response. Ahead of the rear axle, the mid-mounted engine is integrated with a racing transmission based on the RS Spyder. This six-speed constant-mesh transmission with longitudinally-mounted shafts and straight-toothed gears is operated using shift paddles behind the racing steering wheel.

Power generated during braking is stored in an optimized flywheel accumulator, an electric motor whose rotor rotates at up to 36,000 rpm to store energy. Charging occurs when the electric motors on the front axle reverse their function during braking. When the driver needs additional power for acceleration or overtaking, the push of a button calls up the stored energy, deploying it in bursts of up to eight seconds when the system is fully charged.

As in the successful 911 GT3 R Hybrid, the additional power can also be used to reduce fuel consumption by lengthening the amount of time between pit stops.

Hybrid optimized for the racetrack

Racing technology dominates the design of the 918 RSR’s body, where the light, torsionally stiff monocoque is constructed of carbon fibre-reinforced plastic (CFRP). Its functional equipment also underscores the purist, racing character. Doors which open obliquely, a roof-mounted air intake, quick-action locks on the front and rear lids, aerials for pit radio and telemetry, small front wings, splitters beneath the front lip and 19-inch slicks on centre-locking wheels ensure it can be clearly recognized as an experimental racing laboratory.

An unadorned racing atmosphere predominates in the interior of the 918 RSR. A single, figure-hugging bucket seat faces a racing steering wheel and a recuperation display on the steering column, in front of a large display screen to supply the driver with information. Instead of the avant-garde touchscreen centre console of the 918 Spyder, the 918 RSR’s cockpit is split by a minimalist console with rocker switches. Instead of a second seat, the flywheel accumulator is positioned to the right of the console.

History of intelligent performance

The design of the 918 RSR builds on a tradition established by classic Porsche long-distance race cars such as the 908 long-tail coupé (1969) and the 917 short-tail coupé (1971) and fuses it with a postmodern, form-follows-function philosophy.

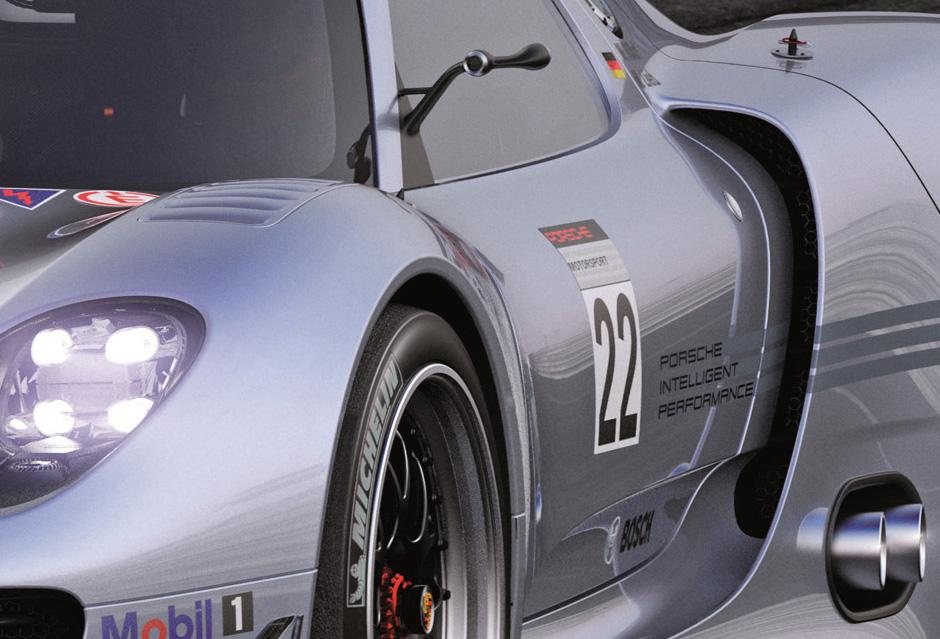

In the 918 RSR, the elegant flow of the body is punctuated by muscular wheel arches, dynamic air intakes and a teardrop-shaped cockpit. A visible fan between the ram air intakes – a clear reference to the Le Mans-dominating 917s – and a large rear spoiler emphasize its function as a racing laboratory. The new “liquid metal chrome blue” paint underscores the sculptured curves of the forms, while the brake calipers and the body’s longitudinal stripes are accented with Porsche hybrid orange.

As a final touch, the 918 RSR’s starting number, 22, pays homage to the 40th anniversary of a major triumph. In the days when overall victories in Le Mans were not yet a routine matter within the Porsche racing department, Helmut Marko and Gijs van Lennep won the 1971 edition of the famous 24-hour race. The record set by their short-tail Porsche 917 – 5335.313 km at an average speed of 222.304 km/h – was only eclipsed in 2010. At that time, their 917, painted in Martini Racing colours, was also an experiment ahead of its time, with an ultra-light magnesium space frame that was a milestone for a Porsche race car.

With the new 918 RSR, Porsche elevates its racing hybrid concept to the next, experimental level, where research into the sustainable improvement of efficiency are tested in extreme conditions on the racetrack – a place where, for 60 years, Porsche has consistently demonstrated its success in lap times, pit stops and overall reliability.

Story by Dr. Ing. h.c. F. Porsche AG.