Porsche has added a powerful new tool to its development arsenal with the commissioning of its road simulation test bench (FaSiP) at the Weissach Development Center. The system can precisely recreate real-world road conditions, allowing engineers to analyze and fine-tune noise, vibration, and harshness (NVH) characteristics far earlier than was previously possible.

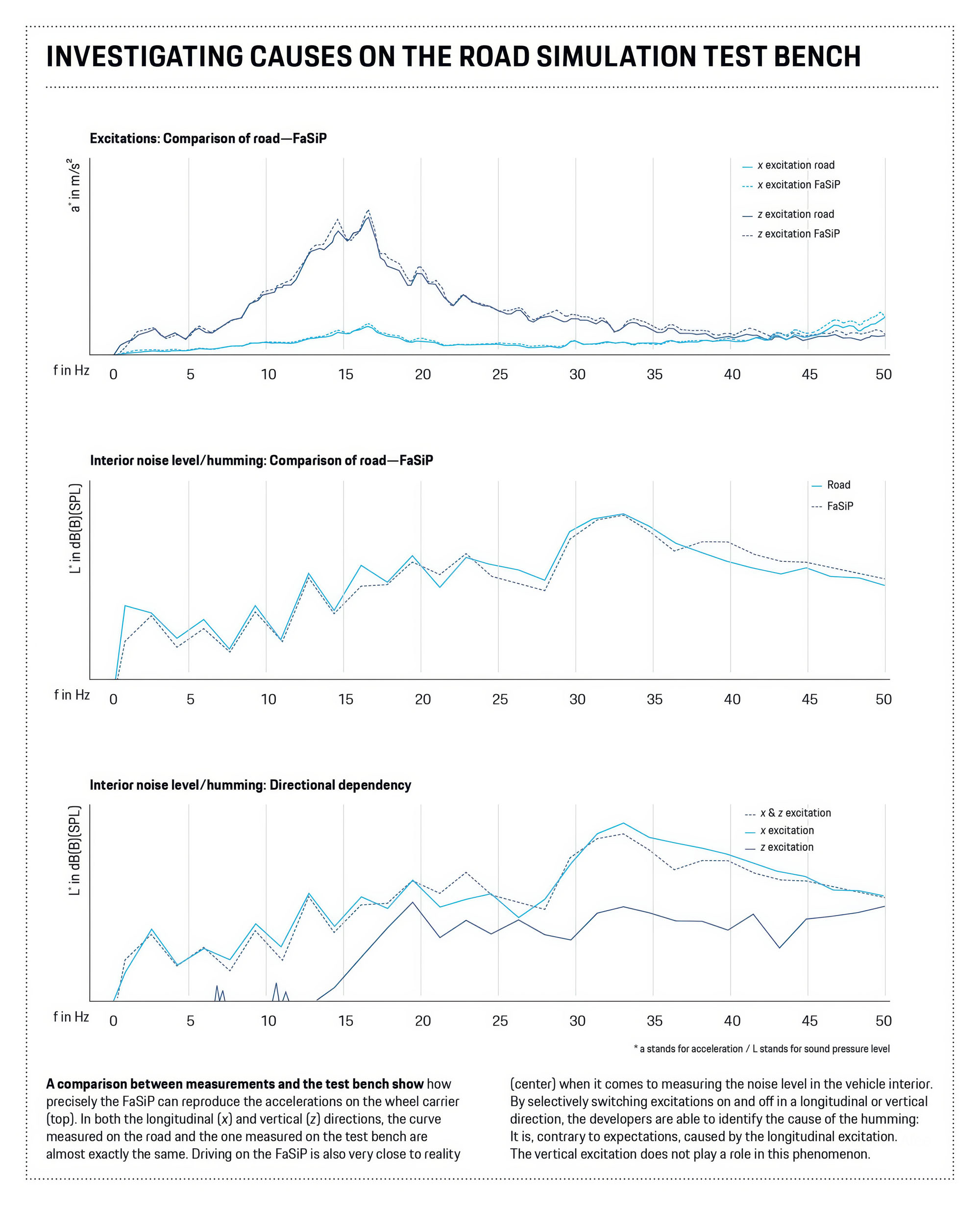

Instead of heading out onto public roads, engineers can now reproduce specific driving scenarios indoors, down to individual axles and frequency ranges. If an unwanted noise appears, excitation from the front or rear axle can be switched off in seconds to pinpoint the source. In one such case, engineers traced a low-frequency hum not to the suspension, but to vibrations in the rear lid—an issue solved with a targeted absorber.

NVH tuning is a critical part of Porsche’s “dynamic fingerprint.” A sports car is expected to transmit meaningful road feedback, while a comfort-oriented model should isolate occupants from it. Striking that balance has traditionally required extensive road testing, often late in development when design changes are costly. FaSiP shifts much of this work to an earlier phase, when even major adjustments are still feasible.

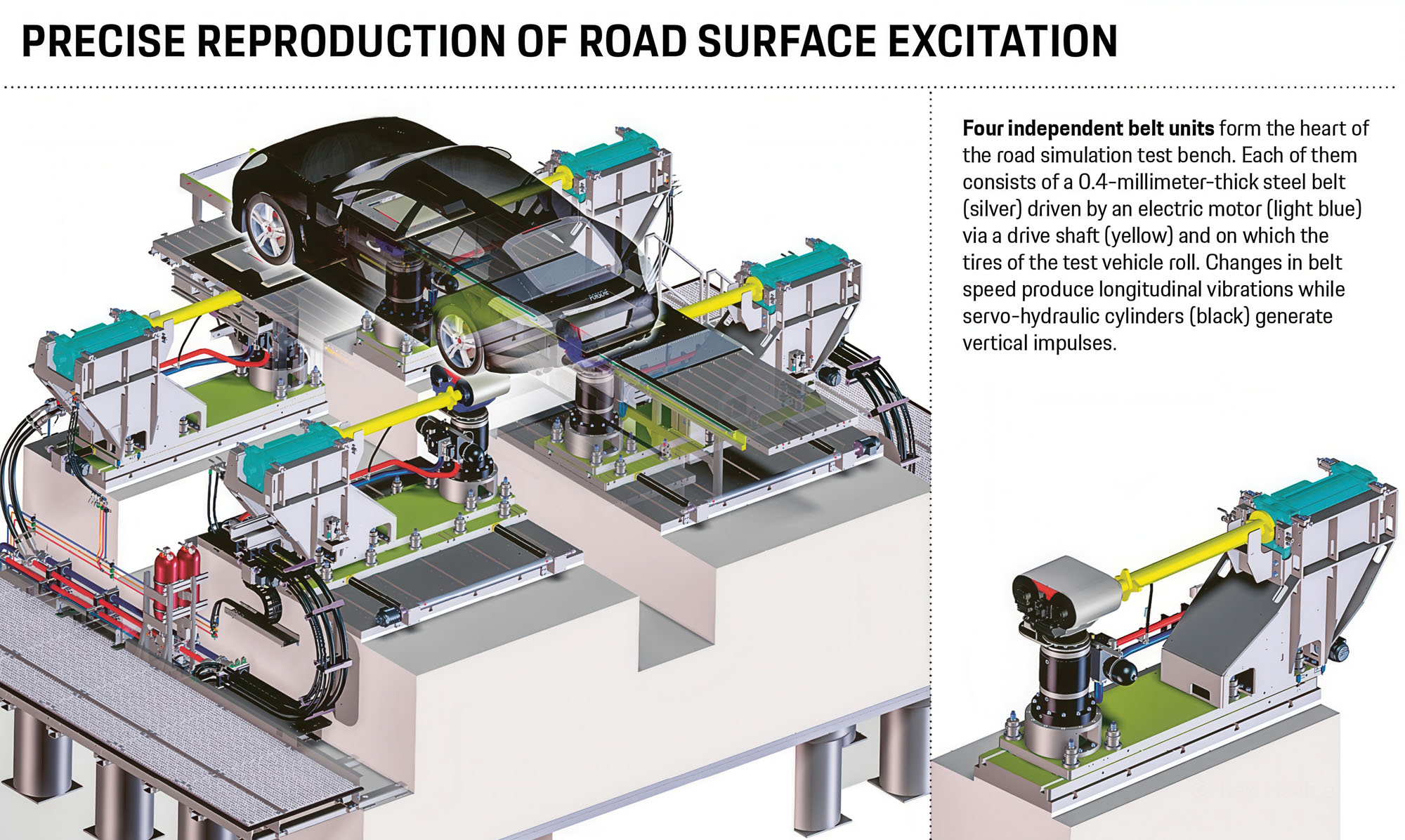

The test bench mounts vehicles—or even individual components such as axles—on four independently driven steel belts. Electric motors generate longitudinal forces, while servo-hydraulic actuators apply vertical inputs, accurately reproducing everything from rough asphalt to maintenance hole covers. Crucially, the wheels rotate during testing, ensuring realistic tire behavior and resonance characteristics.

Beyond development, the system also serves as a diagnostic tool. If an acoustic issue emerges shortly before series production, engineers can recreate the exact conditions under which it occurs, anywhere in the world, and isolate the cause in a controlled environment. Parameters can be adjusted in real time via tablet, turning subjective impressions into measurable data.

Operational since mid-2024, FaSiP can simulate speeds of up to 250 km/h, vertical wheel movements of ±40 millimeters, and frequencies from 0 to 50 hertz—capabilities tailored to high-performance vehicles. It is used internally by Porsche and is also available to external customers through Porsche Engineering.

As vehicle systems grow more complex, the test bench bridges the gap between simulation and reality. Physical testing remains essential for components with nonlinear behavior, such as elastomers, while simpler systems are increasingly handled virtually. The data gathered on FaSiP feeds back into simulations, making them more accurate. Looking ahead, Porsche is exploring AI-assisted comfort evaluation by combining neural networks with automated bench tests. The goal: faster development cycles, lower costs, and ultimately vehicles that feel unmistakably Porsche—long before they ever touch real asphalt.

Above contents © 2026 Dr. Ing. h.c. F. Porsche AG reviewed and edited by Rex McAfee , @rexmcafee

Related Content